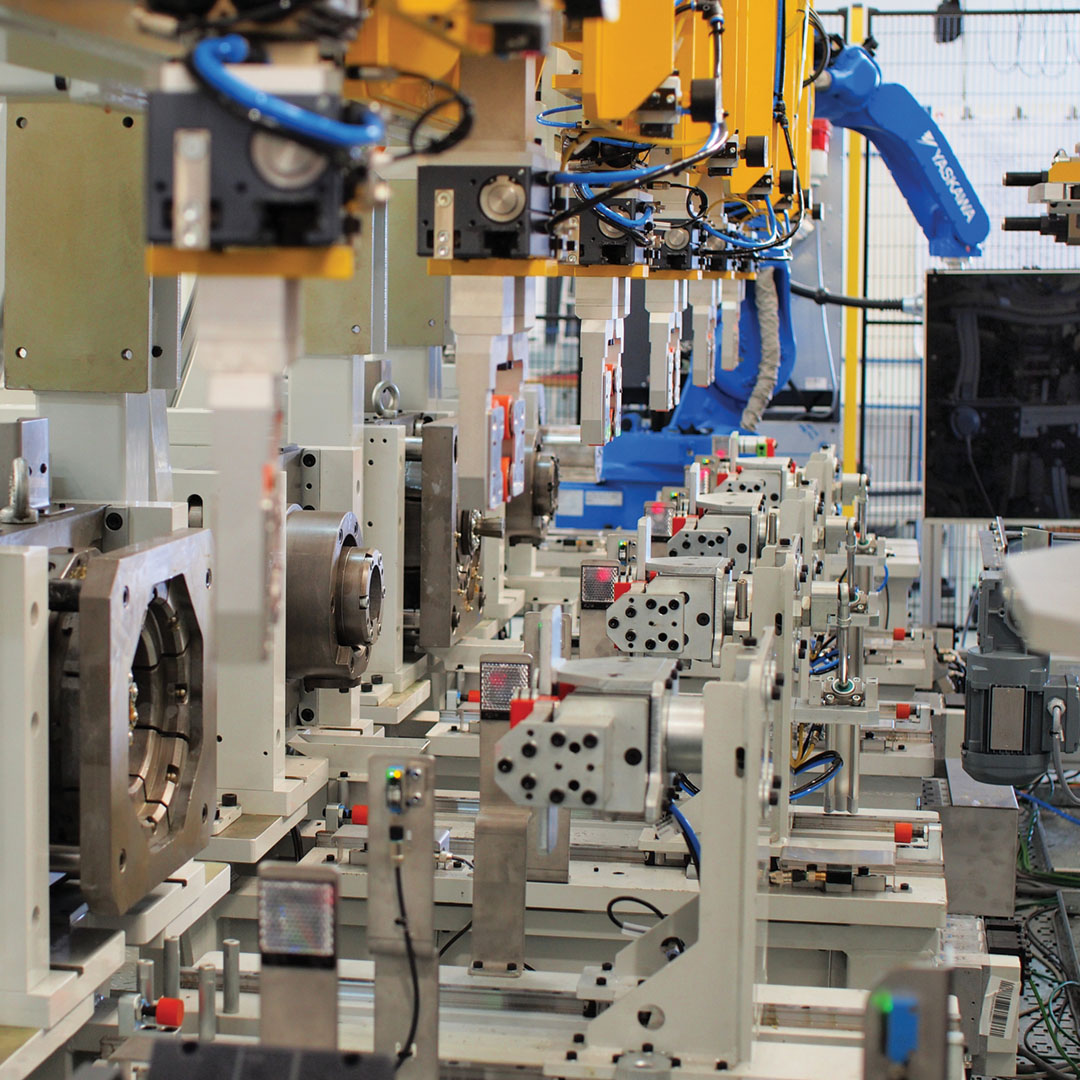

Powertrain Assembly

Jendamark specialises in the assembly of the automotive powertrain, from completely manual to fully automated systems.

EV Battery Assembly

Jendamark designs and manufactures battery pack and power electronics assembly systems for the electric vehicle market.

Catalytic Converter Assembly

Jendamark’s adaptive canning facilities accommodate the most complex assembly requirements to meet varying emissions norms.

Careers at Jendamark

Working for Jendamark opens up a world of career opportunities.

Whether you are passionate about engineering, programming, design or people, this international technology leader welcomes applications from qualified professionals to join our team.

Training

Jendamark offers KUKA robot training courses in Pretoria, South Africa that are internationally acknowledged. Modular in structure, the seminars enable step-by-step qualification on the basis of certified quality standards. At Jendamark, all instructors provide practical training, have many years of experience and are trained in teaching methodology.

Latest News

African tech company of the year

Jendamark Automation is proud to have been named Technology Company of the Year at the Africa Tech Week awards in Cape Town in September. The company was recognised for its technological achievements in developing digitally enhanced component assembly systems for the...

Investing in conservation

While Jendamark applies ecosystem thinking to the development of all our manufacturing technologies, we recently invested in an ecosystem of a different sort in our quest to be the employer of choice. In October, Jendamark Automation announced an investment in...

Sisters for change

Period poverty is the second biggest issue in Africa preventing educational equality for girls. Jendamark Automation has supported the start-up of Sisterhood SA Pty, a visionary health programme that is changing lives with a simple, sustainable sanitary kit. While...

The latest updates from our social media channels

Human skills digitally transform industries, enable greater technology adoption

www.engineeringnews.co.za

It is not the lack of technology in Africa, but rather the lack of skills, that is reducing the ability of companies to adopt new manufacturing technologies, says special purpose machinery manufactur...