by Good News Lab | May 23, 2019 | Jendamark Junction

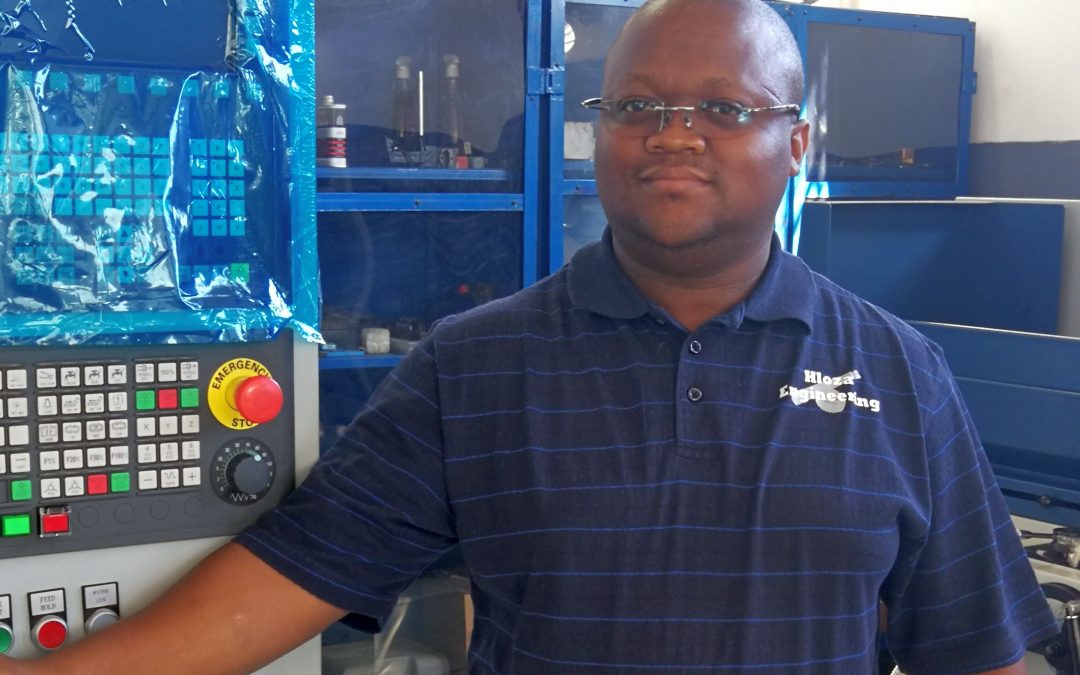

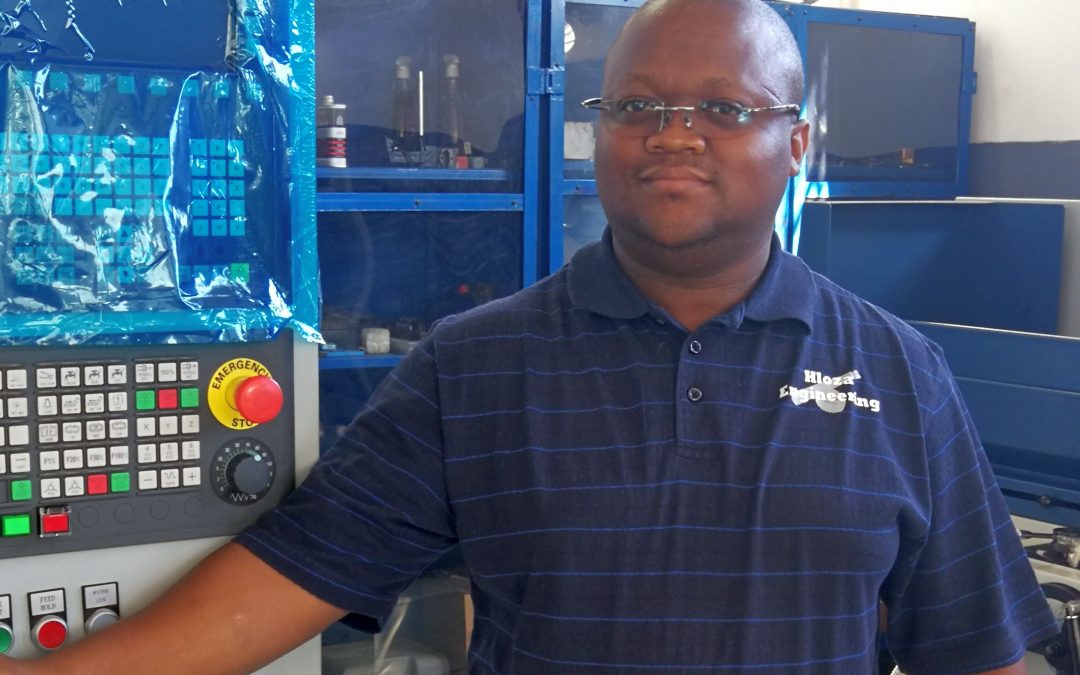

Jendamark-mentored supplier Phumzile Heshu shares how he overcame the odds and what drove him to become a successful businessman with his own engineering company.

As a young boy growing up in an impoverished area of Port Elizabeth, South Africa, Phumzile Heshu liked to play behind Continental Tyre. He would gaze at the massive tyre plant and vow that one day he would work there.

Although he was already driven by ambition, little did Heshu realise that his desire to succeed would one day see him reaching the point where his 10-year plan would be to list his recently established engineering company on the Johannesburg Stock Exchange.

Earlier this year, his business efforts saw him being awarded a R2.9-million grant from the Eastern Cape Department of Economic Development, Environmental Affairs and Tourism, which he used to buy a high-tech machine to increase manufacturing capacity.

Heshu’s Hloza Engineering was the only Port Elizabeth-based company to receive such funding.

“I am living the dream – but I would not have got where I am without the invaluable assistance I received over the past few years from Jendamark,” he says.

WILLING TO WORK

Heshu’s remarkable success story began at school where he may not have been the best scholar but worked tirelessly to achieve the desired results.

He went on to gain a diploma in mechanical engineering and then landed his dream job at Continental Tyre, where he worked as a mechanical technician for almost 17 years.

“But it was time to move on. I wanted to open my own business, so I bought a turning machine and approached a friend, Leroy Green of Modimad Engineering, asking if I could rent some of his machines. After he agreed, all I needed was clients.”

Almost instantly, brands such as Kanu Commercial Body Construction, Goodyear, Continental and Transnet came on board, offering Heshu the chance he desperately craved, but it was not enough, so he plucked up the courage to approach Jendamark.

HELPING HAND

“The Jendamark team were very receptive from the outset and agreed to give me work. While they were very happy with the products I was delivering, I was floundering and running up debts,” he says.

Struggling under the financial constraints, Heshu turned to Jendamark management for assistance. Seeing an opportunity to assist with sustainable small business development, they instantly offered to mentor him in growing his business and help him manage his finances.

A few months later, in 2017, he was doing so well that the decision was made to move away from Modimad and set up his own company – Hloza Engineering.

Once again, Jendamark came to the aid of the fledgling business, helping him to relocate to premises in Schadie Street in Schauderville.

Heshu has since moved across the road, where a modern workshop runs smoothly under his guidance.

EXPANSION PLANS

While he already manufactures steel and aluminium parts for Jendamark as well as Hloza’s other customers, Heshu is still a dreamer at heart and plans to expand even further.

“That was the whole point of the Bhisho grant, which was not easily secured. There were a lot of background checks, testimonials had to be produced and lots of questions asked,” says Heshu.

“When I learnt that I had secured it, I was over the moon. The funds allowed me to buy a state-of-the-art CNC [Computer Numerical Control] machine with a diverse range of functions.

“This, in turn, will allow me to increase capacity and, hopefully, take on more staff.”

When this happens, Heshu will remain true to his roots and offer other previously disadvantaged people the same opportunities Jendamark afforded him.

“When I couldn’t sleep at night for worrying, Jendamark cleared the path for me. They taught me to prioritise, how to control my finances and how to stay focused.

PAYING IT FORWARD

“While I am eternally grateful to them for helping me to realise my dream, I will know when it is time to leave the nest. That’s when it will be my turn to help others in the same way that Jendamark helped me.”

The Heshu family are all involved in building the business’s long-term success.

“My wife, Zoleka, is a director, taking the admin off my shoulders and all four of my children, from my eldest daughter to my youngest child, the only boy, are already a big part of the business,” Heshu says.

“They are the future of my company – one which, if all goes to plan, will be listed on the JSE within the next 10 years. One day I hope to operate on the same level as Jendamark, who gave me the courage to fulfil my dream. Now my dream is to pay it forward.”

by Good News Lab | Nov 14, 2018 | Industry 4.0, Jendamark Junction

Jendamark’s virtual reality room allows designers and customers to explore the possibilities of a new production line in three-dimensional reality via an interactive, computergenerated experience.

The introduction of virtual reality (VR) has had tangible, real world benefits for Jendamark customers by enhancing the design review process.

First, the design team makes the complete production line in VR and a member dons the glasses for a walkthrough of the line. This simple step often highlights potential flaws that would not be apparent during a normal design review.

“It’s about seeing the design with fresh eyes,” says Yanesh Naidoo.

“For example, from a maintenance perspective, can the motor be easily replaced or is it stuck underneath in an unreachable back corner? And, as the operator, can one easily reach all the components, and does it really take the time predicted?”

Naidoo says VR is ideal for ironing out any kinks before the design is handed over to manufacturing and for clients to get a better understanding of its workings before sign-off.

“While the line is in production, VR could also be used to train teams of operators on the virtual version, so that they are ready to hit the ground running when commissioning is complete.”

by Good News Lab | Nov 13, 2018 | Industry 4.0, Jendamark Junction

The Internet of Things (IoT) describes a network of machines, devices and other items that have built-in connectivity, electronics, software or sensors that allow them to share data and improve efficiency for humans interacting with them.

While the idea of a “smart home” or “smart business” may seem far in the future, current estimates suggest that there could be around 30 billion connected devices worldwide by 2020.

For Jendamark, the first application of IoT principles will soon be demonstrated with the addition of a documentation app* to its Odin software platform.

According to Yanesh Naidoo, it is standard practice for the company to deliver all the printed manuals and necessary documentation for a new machine or line as part of the handover process to a customer. Unfortunately, those documents are often misplaced over the years and remain unread until something goes wrong, he says.

“Our solution is to place a 2D matrix or QR code on the main sub-assembly of every machine we make. Then, instead of trying to find the manual, the maintenance technician simply scans the code using the app, which will take him to a link with the correct documentation for that particular sub-assembly.”

Taking this one step further, the IoT could be used to collect data such as the part numbers on a customer’s machine as well as the replacement parts available in his or her storeroom. This information would be available at a glance via the app, thus reducing machine downtime while fixing the problem.

* Currently in development. Available soon for Android devices from the Google Play store.

by Good News Lab | Nov 12, 2018 | Industry 4.0, Jendamark Junction

Augmented reality (AR), as the name suggests, uses technology to augment or add to a user’s experience by superimposing computer-generated images, text and sounds over a real-world environment.

AR creates an immersive and interactive experience for the user, which makes it particularly suitable for assisting operators and maintenance teams on production lines.

Jendamark currently uses AR hardware in the form of Vuzix smart glasses as a bolt-on to its WorkStation app to improve operator efficiency. Instead of consulting a screen or trying to remember each assembly process required, the operator sees the step-by-step process as a visual overlay on the real life workstation through the lens of the glasses.

AR also has a role in quality control by highlighting those parts that need to be visually inspected by the operator once assembled. Once everything is in order, the operator can capture the image, which may be logged as an element in the product traceability chain.

Aside from operator guidance, the glasses also help maintenance workers to access remote support more effectively. Once logged on to the software, the support provider – who may even be on the other side of the world – can see exactly what the maintenance worker sees.

This enables him to guide the on-site worker verbally through the repair process via Skype and by “drawing” helpful sketches, arrows and circles, which are superimposed on the maintenance person’s view of the problem area.

Jendamark’s aim is to develop the AR software that supports all of these functions and plugs seamlessly into its Odin software platform.

by Good News Lab | Nov 9, 2018 | Industry 4.0, Jendamark Junction

Adding a predictive maintenance element to an already efficient automotive assembly line can add unnecessary costs. Jendamark has found a better way to predict machine downtime, which will soon be added as the fourth module to its Odin software platform.

“Typically, a well-maintained machine runs at the industry standard of 95% uptime,” says Yanesh Naidoo.

“It’s already very efficient and the potential 5% improvement doesn’t justify the cost of adding a smart machine or artificial intelligence element that has to analyse data from various machines from scratch, look for abnormal trends, determine the reason for these trends and then take corrective action.”

Naidoo says when it comes to predicting what could go wrong with a machine, the smart solution would be to mine the rich quality data that Jendamark has already been gathering for the past 20 years.

“We’re confident that there is a relationship between the machine downtime and the quality data. When a machine does go down, it can generally be narrowed down to a handful of possible causes.

“Because we already know the outcome, the reverse analysis is much simpler, making downtime easier to predict – without huge cost implications.”

by Good News Lab | Nov 8, 2018 | Industry 4.0, Jendamark Junction

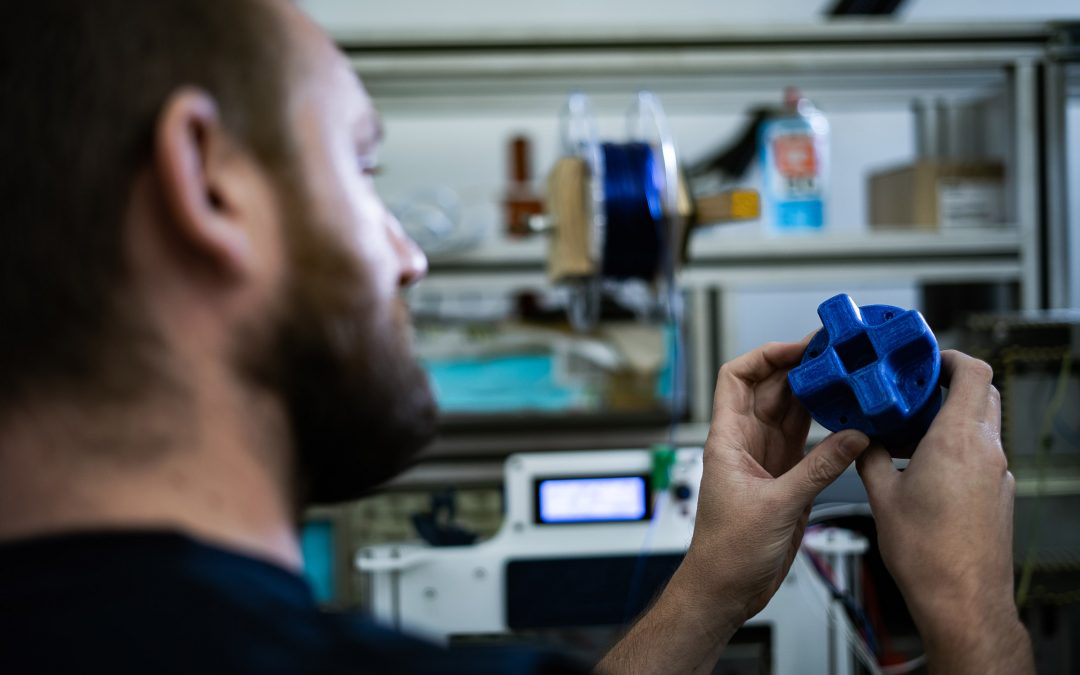

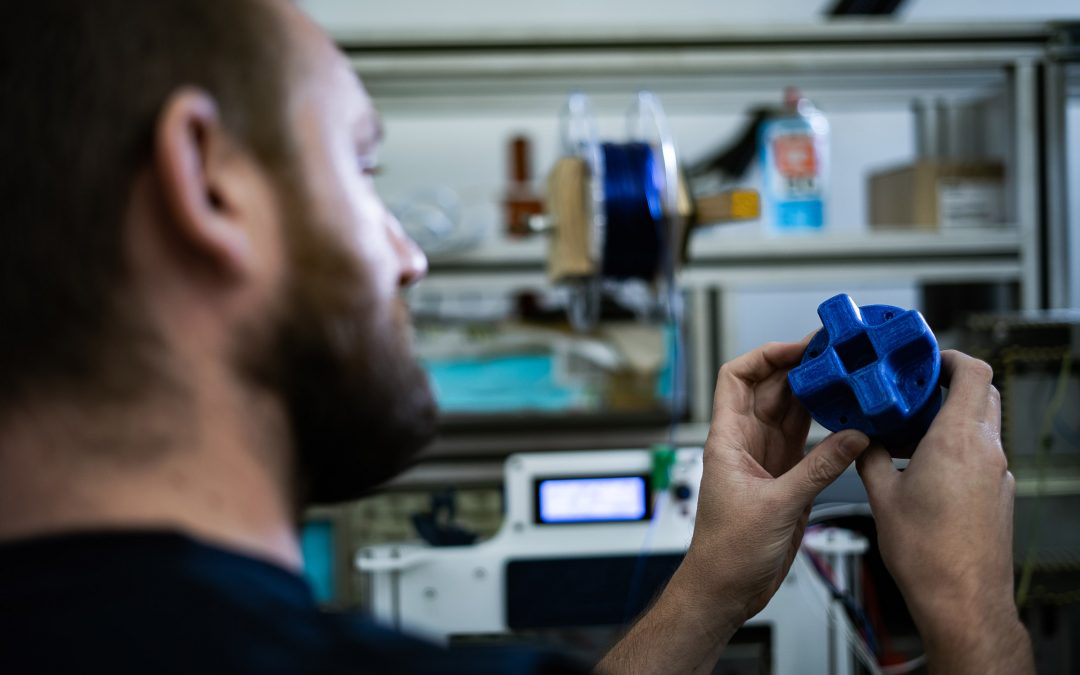

More commonly known as 3D printing, additive manufacturing is gaining momentum in the quest for lightweight parts and minimum material waste.

Instead of machining away metal to fashion a part, additive manufacturing builds it up from scratch, using only the material needed.

“The other big advantage is the idea of topology optimisation – redesigning a part to make it lighter in weight,” says Yanesh Naidoo.

This, Naidoo says, allows for complex lattice-like design, not unlike the bone structure of birds, which is strong but could reduce weight by up to 70%.

“This is a big goal for the automotive industry because it would make cars easier to run on smaller engines. Our assembly machines would in turn require less powerful motors, which would increase their longevity and reduce costs.”

While metal 3D industrial printers remain prohibitively expensive, Jendamark is exploring using industrial robots with MIG weld guns to build up parts.

“The structural integrity still needs to be tested but if it proves successful, a designer could print raw materials overnight and put them into the machine shop the next day,” says Naidoo, adding that it could shortcut the material purchasing process by weeks.

Jendamark’s 3D printer is used to print plastic components, which are especially useful in the development phase, giving designers a feel for the real thing. The initial testing of lines is also done using these.

“Print-on-demand spares for plastic components, such as air vents, are now accepted in the automotive industry worldwide – especially for older model vehicles, where it is no longer cost effective to produce and store large

volumes that may never be used.”