While there has been a lot of hype around Industry 4.0, the digitalisation of factories has not scaled up as expected. A fundamental misconception of what it’s all about and a slow-to-change mindset are two of the major impediments to successful implementation.

A flood of new products on the market and a misplaced focus on the technologies themselves – rather than their practical uses – leaves many customers overwhelmed, says Jendamark innovations director Yanesh Naidoo.

“There are a lot of buzzwords, like the integration of IT and OT on the shop floor, and I think people get befuddled by all the jargon and consulting talk,” Naidoo says.

“Simply put, Industry 4.0 is just a set of technologies that you can use to solve your manufacturing problems.”

A tech toolbox

It helps to think of Industry 4.0 as a toolbox with a set of tools inside, he explains.

“However, having a toolbox full of tools mean nothing unless you do something with them. You must first understand the problem you’re trying to solve in your factory, and then invest in the right tool for the job.

“A hammer has many uses, but how you apply it depends on your situation. Also, you may be trying to hammer in a screw, when what you really need is a screwdriver.”

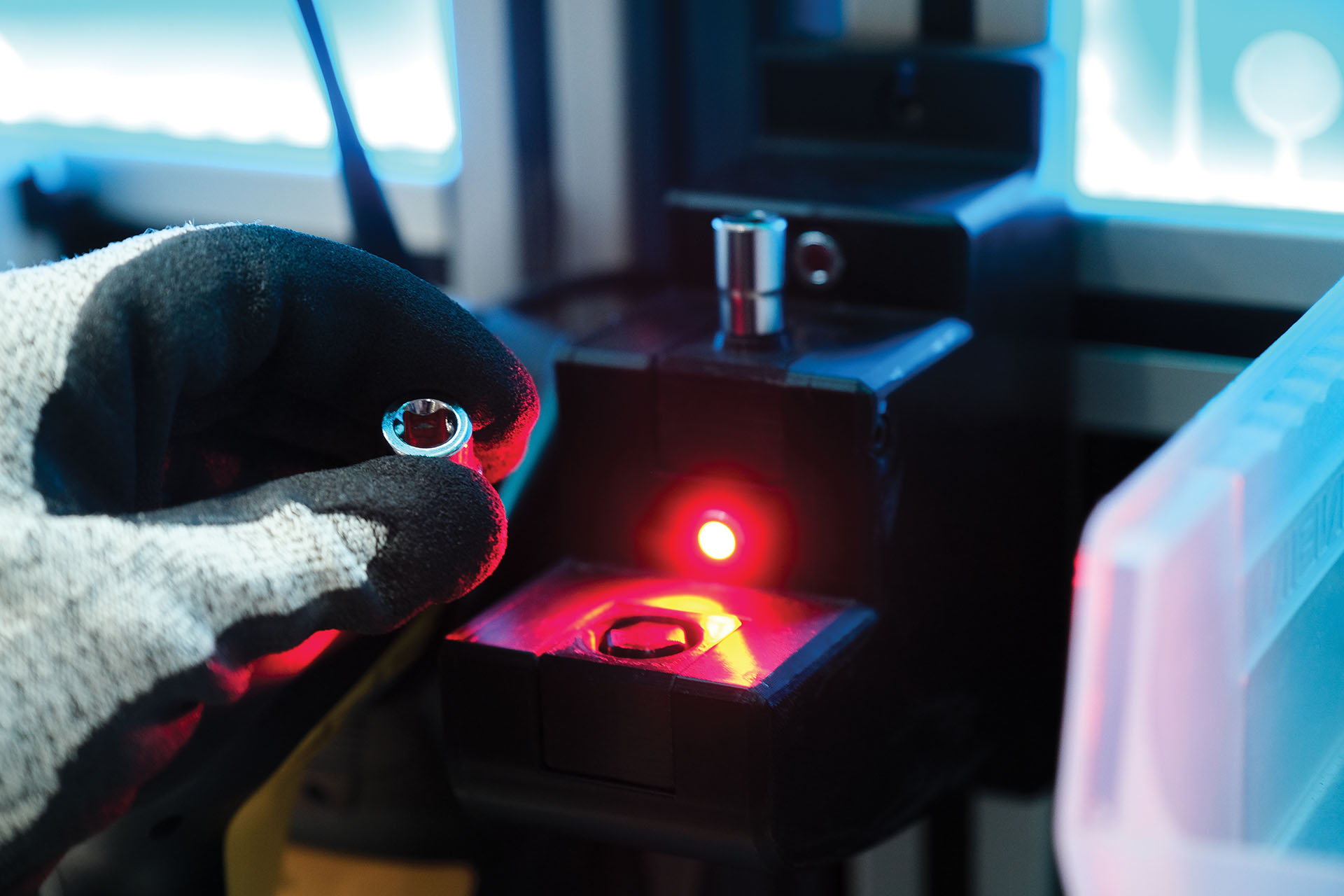

For example, if frequent machine breakdowns are a problem, Naidoo says an anomaly detector could help to highlight a downward trend in performance, which could be addressed and fixed before it becomes a serious problem, avoiding unnecessary downtime.

Proactive vs reactive approach

“Essentially, Industry 4.0 is about using tools to be more proactive, rather than reactive. But it all means nothing if our mindset doesn’t change.”

Naidoo draws parallels with the preventative approach to health and longevity outlined in Dr Peter Attia’s book Outlived.

“Medicine 2.0 has been extremely successful in treating lifestyle diseases such as Type 2 diabetes. You go to the doctor, they diagnose you and give you insulin, which has saved many lives.

“But this book argues for a transition to a more preventative approach to medicine. Don’t wait to get diabetes; monitor your health, get the check-ups, make the necessary dietary and lifestyle changes, and prevent it from happening in the first place.”

Factory health screening

Until now, manufacturers have not had the technology or toolbox to take a preventative approach to maintaining the overall health of their factory assets, but Industry 4.0 is changing all that. The difference, Naidoo says, lies in the data that comes from continuous measurement rather than a static, point-in-time measurement.

“A factory audit, like a glucose test for diabetes, is not an accurate reflection of your lived reality,” he says.

“For the glucose test, you fast the night before, then go for the blood test. If your results are just within the acceptable range, everything is deemed fine, so you revert to your bad dietary habits. You’ve prepared your body for the test but that’s not how you live your life, and you can expect future problems if you don’t continuously monitor your glucose levels and make lifestyle changes,” explains Naidoo.

Similarly, he says, a factory audit usually runs quality and production checks using the best operators, the best maintenance team, and the best raw materials on the line.

“It’s a fake perception. What you need is live information from the production line that can be used to understand where the problems are and improve the process by making iterative changes.”

The problem with OEE

With the right technology in place, everything on a production line can be measured continuously – from operator speed to press force and scrap rates. The problem, Naidoo believes, is that every plant manager’s performance is measured on Overall Equipment Effectiveness (OEE), which is a widely used, retrospective, reactive measurement.

“It tells you what happened yesterday, but nothing about what is going to happen tomorrow. Plant managers should be measured on what is going to happen, because they can still have an impact on that.”

Like the human body, all production lines are not the same, so trying to meet a set OEE key performance indicator of, say 85%, might not be practical, given the age of the line, or the quality of the incoming raw material.

“The measurement needs to be unique to a particular production line. As the line gets older, there’s more wear and tear, and breakdowns. So, you need dynamic baseline data that reflects the current situation and can be improved year on year.”

Naidoo says technology can help to predict the risks associated with the people, machine, and product parameters on the shop floor. “Then you can proactively do things to mitigate the risk before it happens.

“We know everyone is under pressure to produce. But at some point, when you see the data trends going in the wrong direction, a manager must have the foresight to make the decision to stop the line and fix the problem, knowing it’s eventually going to hit the limit.

“It’s critical to be proactive because when it hits the limit and things break, you will stop the line. And you will have to make the time and budget to fix it. You’ll have far less downtime if you make adjustments when you notice a spike in anomalies, even if they’re still within tolerance.”

Competitive advantage

Ultimately, Naidoo says, Industry 4.0 is a must for manufacturers who want to remain in business in a rapidly changing environment.

“The world is getting far more competitive. You have to squeeze every single cent you can out of your production process. One of the key things is to become more agile because variation of product, or mass customisation, is now a demand from customers. Your production line needs to be able to adapt quickly and effectively, and also manage fluctuating volumes, without massive capital cost or too much downtime.”

So, what does practical digitalisation look like and where does one start?

If a customer is still hesitant to make changes on the production side, Naidoo says one easy entry point is digitising the maintenance function to facilitate the scheduling of tasks and a more preventative approach to asset health.

“Then once you start seeing the benefits, you can start optimising your assembly process efficiencies by introducing, for example, operator guidance systems. If you choose the right supplier and technology, digitalisation is designed to start small and grow with you step by step, so you get your return on investment.”